Echo Plasma-cut

—

Advanced Info

—

Picture only illustration***

—

Please note that, all 3-axis Echo CNC models can be converted to plasma table*.

—

Key points:

– Made in EU (Ireland).

– Ready to work.

– Free local & online training.

– Life time technical support.

—

Technical details:

– Professionally laser cut solid carbon steel frame structure, NO weld system.

– Prismatic HG20 linear rails on all axis.

– Inductive limit switches on all axis.

– Auto tool sensor.

– Work area: Y2450, X1250, Z95.

– Power supply: 250/400V

– Weight is about ~ 350KG!

—

Setup options:

Echo 2750 Plasma Pro.

– Hypertherm 85A, 3phase setup + THC

– High torque Nema34 & Nema 23 hybrid servo system & powerful driver combination.

– Full helical rack pinion system on X,Y,A axis, ball-screw driven on Z axis.

– Rapid speed/milling speed up to: ~24.000mm/min.

– Water bed installed.

—

Echo 2750 Plasma Standard.

– Hypertherm 45A, single phase setup + THC.

– High torque Nema34 & Nema 23 stepper motors & powerful driver combination.

– Full helical rack pinion system on X,Y,A axis, ball-screw driven on Z axis.

– Rapid speed/milling speed up to: ~12.000mm/min.

– Water bed installed.

—

Helical Rack Pinion System.

Helical teeth gears provide continuous engagement along the tooth length, that is why more quieter and more efficient than straight tooth gears. Helical tooth gears resemble spur gears in the plane of rotation, but include teeth that are twisted along a helical path in the axial direction.

—

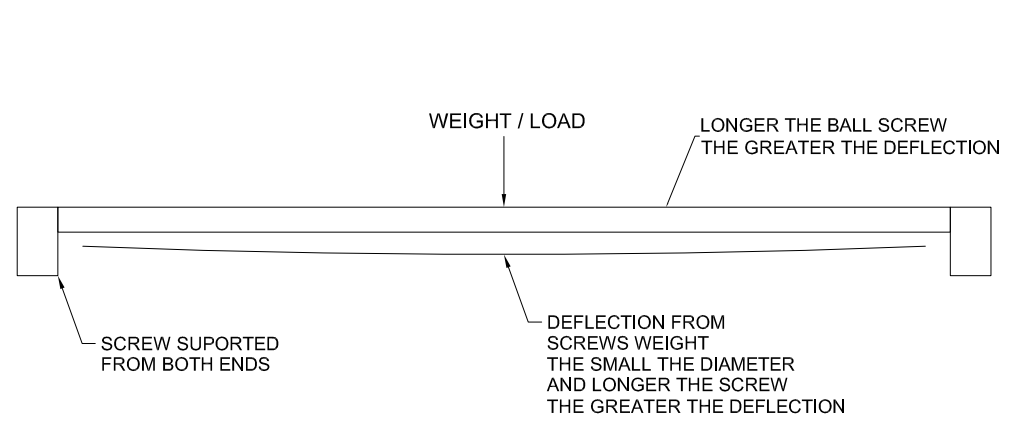

Ball-screw, but not always…

The above illustration shows the longer the ball screw length, the more sag the screw will have. Under high speed motions, it’s the sag or deflection that causes vibrations, which will resonate throughout the machines mechanics, ultimately resulting in poor cut quality. That’s why CNC FACTORY uses the helical rack pinion gear system on 8×4 CNC machines or above.

—

Free run rack pinion system:

—

—

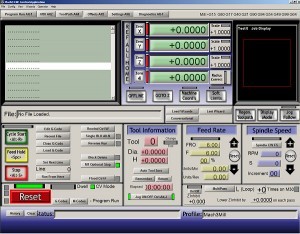

Mach3 control System.

—

Mach3 is the most intuitive CNC control software. Mach3 turns a typical computer into a CNC machine controller.

It is very rich in features and provides a great value to those needing a CNC control package.

—

—

Here are some of the basic features and functions provided by Mach3:

- Converts a standard PC to a fully featured, 2-6-axis CNC controller

- Allows direct import of DXF, BMP, JPG, and HPGL files through LazyCam

- Visual Gcode display

- Generates Gcode via LazyCam or Wizards

- Fully customizable interface

- Customizable M-Codes and Macros using VBscript

Website : http://www.machsupport.com/software/mach3/

—

Vectric software compatibility.

—

We recommend : Cut2D, Cut3D, V carve Pro, Aspire, and Photo V carve-softwares !!

—

Cut2D is typically being used by CNC machinists and is ideal for a wide range of machining applications.

—

—

Here are some of the basic features and functions :

- Automatically converts CAD drawings and Graphic designs to GCode / CNC Toolpaths.

- Opens most industry standard 2D vector drawing formats DXF, EPS, AI & PDF file formats.

- Pocket Machining with either raster or offset machining patterns, plus the option to ramp the cutter into the material.

- Profile Machining-running the cutter around the outside, inside or on the selected geometry, with the option to ramp the cutter into the material.

- Automatic cutter diameter compensation for toolpaths ensures parts are cut to the required size. Simply select the shapes and Cut2D compensates for the cutter diameter and shape.

- Interactive Tab / Bridge placement to ensure parts are securely held in place when cutting from sheet material.

- Automatic calculation for Outside and Inside cutting when multiple shapes are selected.

- The option to Ramp the cutter into the job is very important when cutting hard materials because it reduces the load on the bottom of the cutter.

- Drilling with option for Peck drilling cycle.

- 3D Colour and 2D wireframe toolpaths Previews shows exactly what the part will look like when machined.

Website : http://www.vectric.com/index.html

—

—

Compact multipurpose CNC plasma cutter with excellent price/value!

Prices:

–2750 Fully assembled & ready to work CNC table only : 11500,-€*

(CNC table without plasma cutter.)

–2750 Plasma Standard : 16750,-€*

(Single phase Hypertherm 45A setup.)

–2750 Plasma Pro : 19750,-€*

(3 phase Hypertherm 85A setup.)

—

*The Z axis has several mounting holes for the plasma torch.

*The control box has a relay output to start the plasma cutter

**2 years manufacturer warranty for all Echo 2750 pro models.

—

Do you need premium services?

Click here to read more : Premium Services

.

.

***Any question please feel free to contact me .

*** cnc router, cnc cutter, cnc engraver, cnc plasma, cnc laser, cnc lathe, 10×5 cnc, 8×4 cnc, 6×4 cnc, 4×4 cnc, desktop cnc ***

Total views : 350415

Total views : 350415